MACHINE PARK

Washing and drying units or all other devices on the parkour can be recorded in the system and easily followed by failure and repair history.

RFID Laundry Management System

Provides service in city hospitals and private laundries

It keeps running smoothly

Textile is cleaned again every day

ECELMS is designed with a qualitative and parametric structure that can meet the needs of many business fields.

Hospitals

Hotels

Restaurants

Private Laundries

Dry Cleaning Companies

Official Institutions

Companies that providing textile

washing and rental services

Softwares produced for laundries draw an operation frame that generally consists of textile counts, and they are insufficient in many issues required by the sector.

ECELMS has been developed to provide control across the laundry, entire work flow from distribution to textile recieving beyond the counting. Control the pre-accounting procedures, machinery and other equipment, employee, chemicals and other expense that used.

In all stages, textiles are recognized and counted by the system with special RFID labels that are glued or stitch on them. It can resist to water, high temperature and pressure.

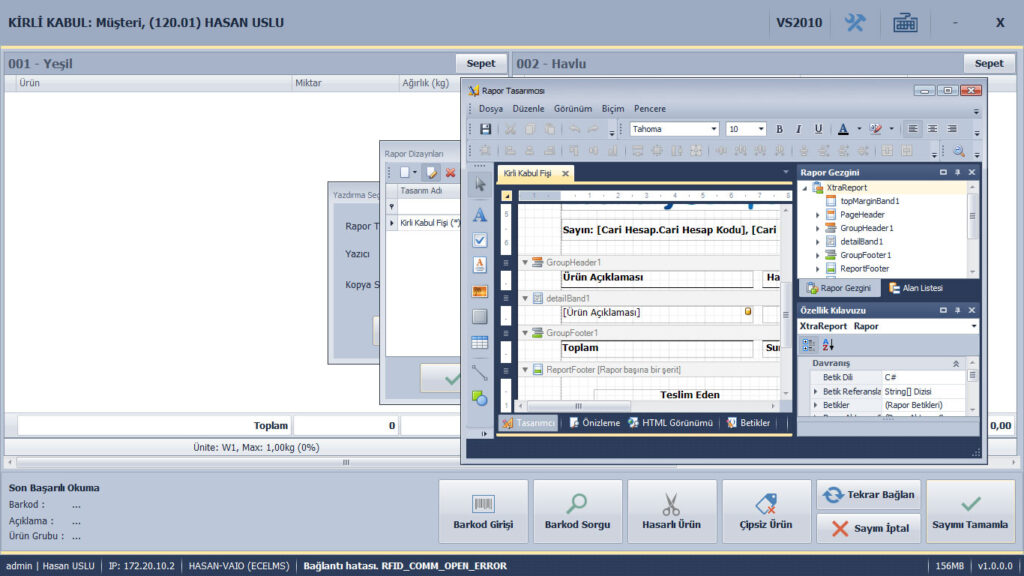

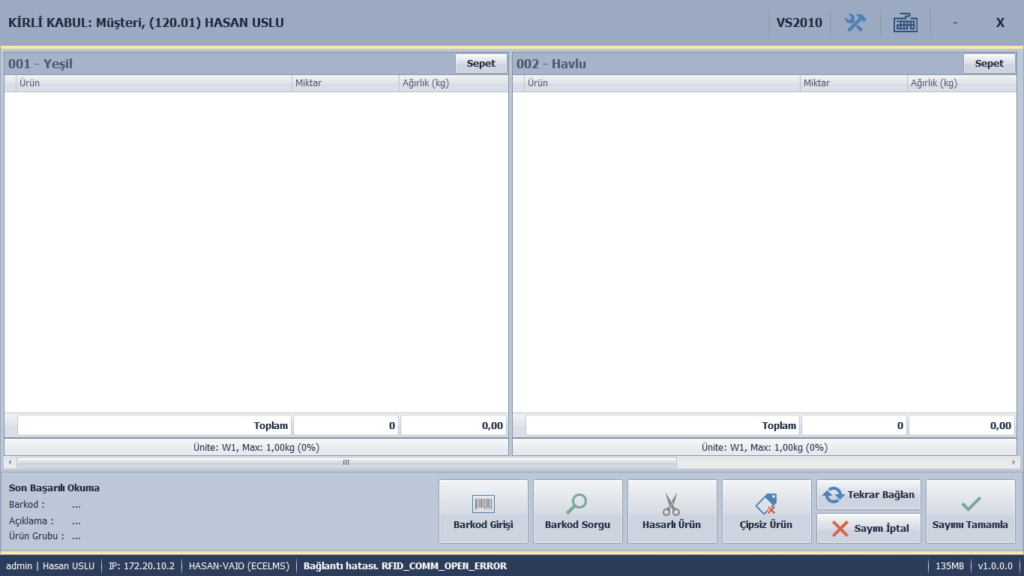

It is specially designed for laundries with heavy work flow. RFID reader provides the opportunity to count up to 100% accuracy. Receiving dirty textile products and existing records are recorded into central system. Depending on the capacities of the washing units, the counting process can be stopped when the capacity of the relevant machine is full, or counting can be continued/shifted to the machine with higher capacity. In this way, it is possible to improve the durability of

the washing units by preventing excessive capacity.

It instantly counts all the RFID tags on textile products. When the product group reaches the maximum number of packing, it automatically prints label.

It informs the user by giving a warning for the textiles that has expired or damaged.

New generation wall mounted stand with RFID readers can read the textiles in the car or basket up to 100% accuracy. When the reading is completed the delivery receipt can be printed optionally.

Alternatively, clean output operations can be done by reading the packaging labels with barcode readers.

ECELMS consists dirty receiving, washing, packaging, clean output and delivery stages, also includes dirty receiving and clean delivery modules for employee

uniforms, dry cleaning module for patients, hotel guests or businesses serving third parties.

Mobile RFID is an industrial device that has reader and touch screen on it. Its used for making clean textile deliveries to rooms, whole textile counting and controling operations. It speeds up the counting process with high reading capacity and provides full control in the work field. Through working integrated with the central system, it helps to transfer offline data transactions to the central database.

Uniforms, workwear or any textiles used by the staff of the hotel, hospital or other institution are associated with that staff. Dirty receiving and clean delivery processes of the registered textiles can be followed through the system. Confusion can be prevented by following staff uniforms one by one. Action receipts can be printed for uniforms that are received and delivered. Detector function in the mobile application provides ease of use for finding staff’s uniform in textile those belonging to any staff among the mixed textiles.

It is used for the receiving, delivering and pricing of textiles to patients, hotel customers or third person.Receipts of dry cleaning can be printed for textiles those received or delivered. Payment can be made on delivery and invoice can be printed.

Washing and drying units or all other devices on the parkour can be recorded in the system and easily followed by failure and repair history.

Employee productivity can be analyzed with informations such as working hours, absenteeism and its reason.

Employee salary, chemicals, electricity, water, fuel and other expenses can be recorded and reported.

Instant status can be viewed by accessing the system from anywhere with internet access

Control of customer complaints, solution times and solution stages increases customer satisfaction.

All output types can be redesigned in detail through the back office application, multiple designs can be created within the same output type.

Current, stock, delivery note, invoice and expense item transactions can be integrated with the system.

Visual reporting functions support business management and decision processes

Advanced web service structure enables data transfer to third party software. Workload can be reduced by integrating RFID codes. For example summary or detailed input and output transaction datas into hospital, hotel and any other system.

Third party alarm systems (entrance/exit doors) can generate alarms for registered RFID codes by making instant queries 24/7 via web services.

Textile stock tracking based on warehouse

Warehouse correction and loss with inventory system

Mobile application

Pre-accounting

Current account tracking

Multiple shipping point definitions for current accounts

Chemicals and other card stock

Delivery note and billing processes

Employee absences

Customer complaints

Water hardness values

Equipment failure & repair records

Daily business expenses and records

Identifying damaged, chipless and stained textiles

Multiple pricing for textiles that are repaired

Prevention of reading unwanted RFID tags with

blacklist structure

Detailed user authorization

Private Reports based on customers

Web-based, device-independent reporting system

24/7 reliable operation with SQL database structure

Dirty textile input

Washing follow-up

Packaging and labeling

Clean output

Dirty uniform input

Clean uniform output

Dry cleaning section dirty input

Dry cleaning section dirty output

Whole textile registration

Whole textile disposal (decommissioning)

Whole textile loss identification

Whole loop editing

Ironing information and instruction screen

RFID basket / container tracking

Receiving dirty textiles

Packing and labeling

Clean warehouse delivery

Clean textile distribution to services

Inventory count

Textile detector

Fast overall counting

Pin code entry for transactions that require verification

Supports for mobile bluetooth printing in all functions

Online or offline working with the central system

Data transfer synchronization when it turns to connect

to system

Frequency | 860 - 960 Mhz |

RFID Chip | Class I Gen 2 ISO-18000-6C |

Dimensions | 20 x 59 x 1.8 mm |

Reading Range | 3 m |

Material | Epoxy /Polyester |

Max. Heat Resistance | 200°C / 15 sec |

Tunnel Washing | 90°C / 15 min |

Pre-Drying | 160°C / 30 min |

Tunnel Ironıng | 185°C / 30 min |

Sterilization | 134°C / 20 min |

Squeezing | 60 bar |

Warranty | 200 times use, 3 years |

Readers can read between 860 – 960 Mhz, and up to 600 tags can be read per second.

System’s advanced reading capability, detailed antenna and signal strength options can be configured, enables the reading function to be improved and ! maximum reading efficiency can be achieved even in difficult physical conditions